Groin: MAZAK

Expensive materials used in aerospace, energy and medical industries can be formed into near net shapes by laser metal deposition to reduce total production time. Additive manufacturing of different types of metals can be used for increased durability and anti-corrosiveness.

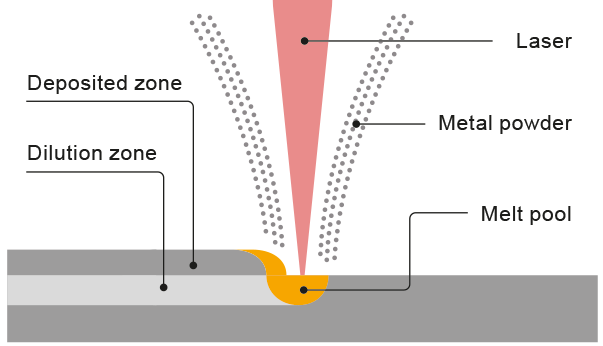

Laser from the nozzle center melts the base material and the metal powder supplied from around the nozzle.

Heat source:Â Laser

Laser resonator:Â Direct Diode 1.0 kW, 2.0 kW, 4.0 kW, 6.0 kW

Spot diameter:Â To suit the application

Material:Â Metal powder

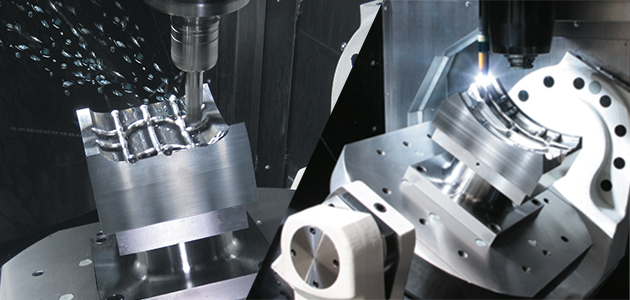

Advanced additive manufacturing (AM) technology integrated into multi-tasking 5 axis machining centre.

Wire arc AM is suitable for a variety of processes, such as; component near net shape, repair of molds, and other AM applications.

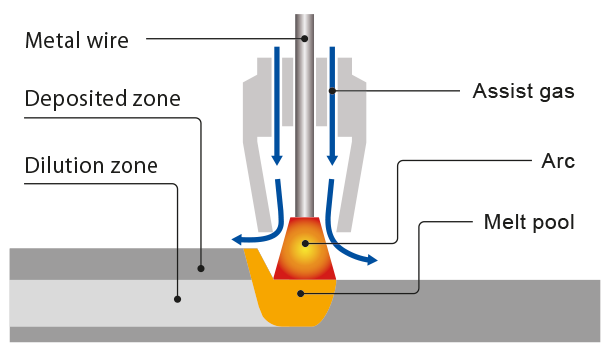

Metal wire melted by an electrical arc is deposited on a base material. Programmable welding automation is performed.

Heat:Â Electric Arc

Type of arc:Â MIG

Max. current:Â 300 A

Material: Metal wire Φ1.0 mm (Φ0.04“), Φ1.2 mm (Φ0.05“)

A near net shape workpiece normally requires a casting to be produced. With additive manufacturing technology, the casting process is not necessary for considerably reduced production time.

Tire Mold (Automotive) Base material: A5052 | Shaft (General Machinery) Base material: SUS316 | Screw Conveyor (General Machinery) Base material: SUS304 |

| Â  | Â Â  |

Material cladding can be performed on a different type of base material to increase durability.

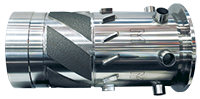

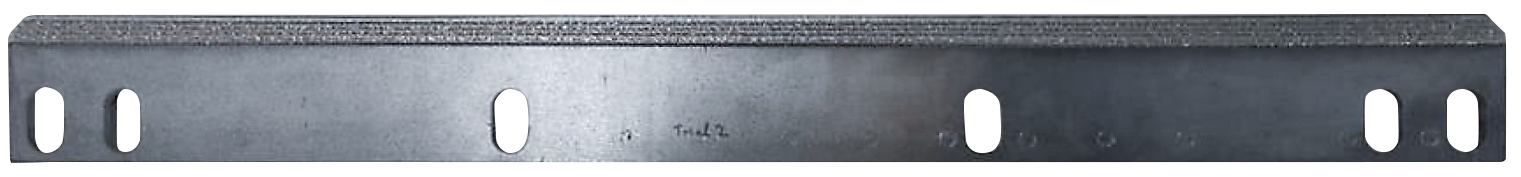

Impeller (Automotive) Base material: SUS316 | Roll die Cutter (Die and Mold) Base material: S45C | Blade (Agricultural Equipment) Base material: SUS304 |

| Â  | Â Â  |

For the machining of a repair part, additive manufacturing and finish machining can be performed in a single workpiece setup.

Turbo Impeller (Automotive) Base material: Inconel 718 | Sheet Metal Mold (Die and Mold) Base material: SKD61 |